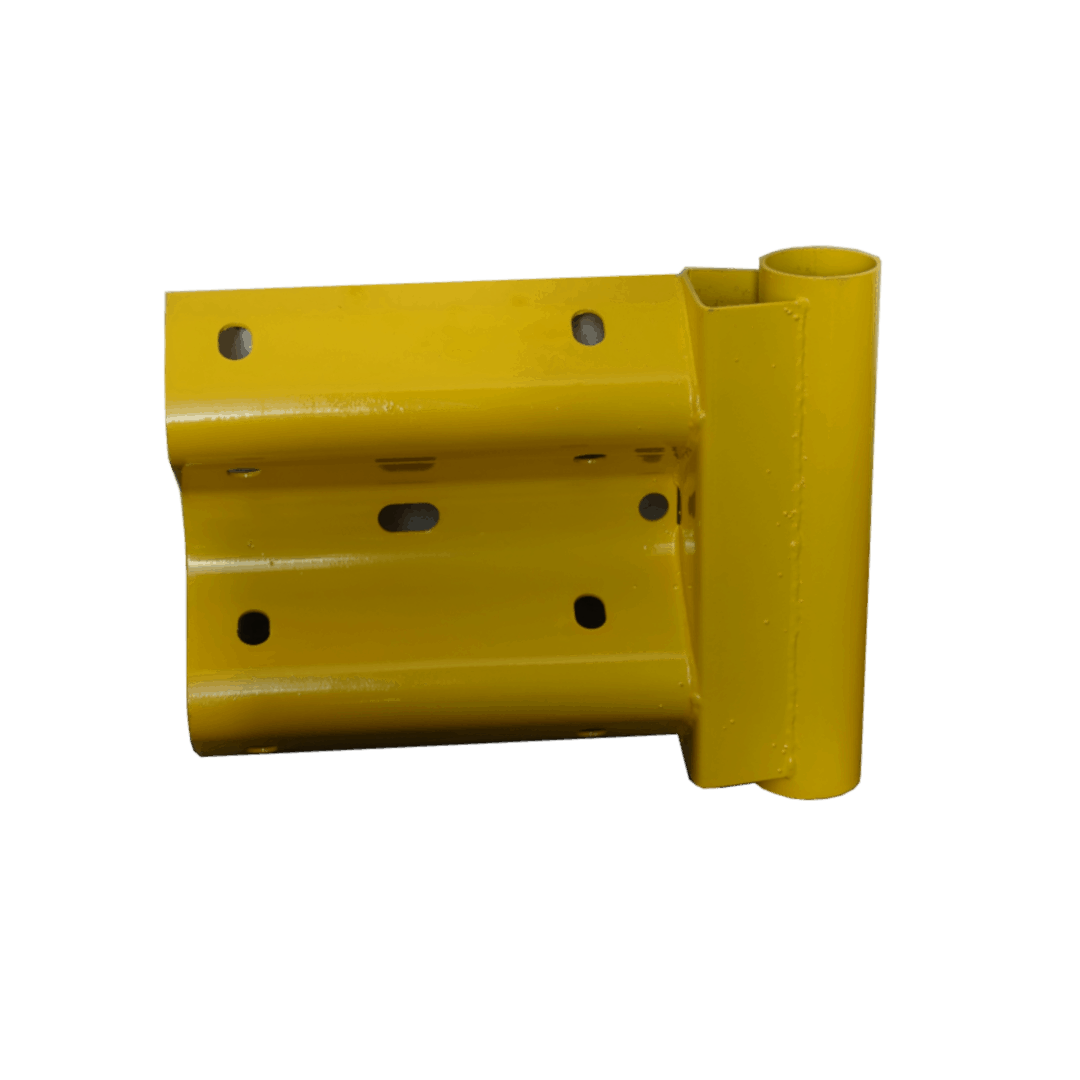

Pedestrian Scroll Ends – Steel – Powder Coated Safety Yellow (AR11Y)

£50.00

Pedestrian scroll ends -Powder coated safety yellow – suitable for car parks and public areas.

| 1-10 | £50.00 |

| 11-20 | £48.00 |

| 21-100 | £46.00 |

| 100+ | £43.00 |

In stock

| Quantity | Fixed price |

| 1 - 10 | £50.00 |

| 11 - 20 | £48.00 |

| 21 - 100 | £46.00 |

| 101 + | £43.00 |

Description

Pedestrian Scroll Ends

Pedestrian Scroll Ends are designed without sharp edges to catch clothing or cause any injuries, they are ideal for use where armco barrier meets a doorway. Requires 4no M16 Lap bolts.

The pedestrian scroll ends is an ingenious safety solution, created with round edges that won’t snag clothing. Compared to the sharp corners of traditional Armco beams, this rounded design provides a secure barrier in areas like shopping centre car parks and walkways where pedestrians are constantly passing through.

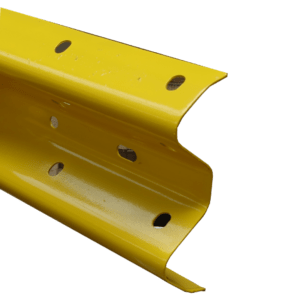

Why use Powder Coated Safety Yellow Pedestrian Friendly Scroll Ends?

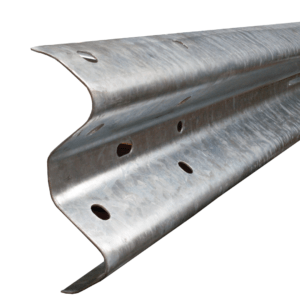

When it comes to off-road crash barriers, the choice between powder coated safety yellow RAL1023 pedestrian scroll ends and galvanized-only options involves considering several factors. In this explanation, we will discuss the advantages of using powder-coated yellow scroll ends over galvanized-only barriers.

- Visibility: The bright yellow colour of RAL1023 powder coated provides high visibility, making it easier for drivers to spot the crash barriers, especially in low-light conditions or during adverse weather. This enhanced visibility can significantly improve safety and help prevent accidents by alerting drivers to the presence of barriers.

- Pedestrian Safety: The term “pedestrian-friendly” indicates that the scroll ends are designed with the safety of pedestrians in mind. The scroll ends have rounded edges and a smooth surface, reducing the risk of injuries to pedestrians or cyclists in the event of a collision. Galvanized-only barriers, on the other hand, often have sharp edges that can cause severe harm to pedestrians or cyclists.

- Aesthetic Appeal: Yellow RAL 1023 allows for a wide range of colour options, including the distinctive safety yellow. This can enhance the overall aesthetics of the crash barriers, making them visually appealing while serving their primary purpose. Galvanized-only barriers, in comparison, have a plain silver appearance that may not be as visually striking.

- Corrosion Resistance: While galvanized-only barriers offer good resistance to corrosion, powder-coated barriers provide an additional layer of protection. The powder coating acts as a barrier against moisture and prevents the underlying metal from coming into contact with corrosive elements. This extra protection prolongs the lifespan of the crash barriers, reducing maintenance requirements and ensuring long-term durability.

- Environmental Considerations: Powder coating is an environmentally friendly option compared to galvanizing. The powder coating process emits lower levels of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) compared to traditional liquid coatings used in galvanization. Additionally, powder coating does not require the use of harmful chemicals like those involved in galvanization, making it a safer choice for both workers and the environment.

- Easy Repair and Maintenance: If a powder-coated barrier gets damaged or scratched, it can be easily repaired by applying a fresh coat of powder coating to the affected area. This localized repair maintains the barrier’s appearance and protective qualities. Galvanized-only barriers, on the other hand, require more extensive repair work, such as galvanizing the entire section affected by corrosion, which can be time-consuming and costly.

In conclusion, using powder-coated yellow RAL1023 pedestrian-friendly scroll ends for off-road crash barriers offers numerous advantages over galvanized-only options. These include increased visibility, improved pedestrian safety, aesthetic appeal, enhanced corrosion resistance, environmental friendliness, and easier repair and maintenance. Considering these factors, powder-coated barriers provide a more comprehensive solution that prioritizes safety, durability, and visual impact, making them a favourable choice for off-road crash barrier applications.

Pedestrian and Cyclist Hazards: Crash barriers are often located in areas where pedestrians and cyclists are present. Sharp edges on barriers can pose significant risks to these vulnerable users. In the event of a collision, pedestrians or cyclists may come into direct contact with the barriers, leading to severe cuts, abrasions, or even impalement, resulting in serious injuries or fatalities.

Maintenance and Repair Difficulties: Sharp edges on crash barriers can also create challenges during maintenance and repair activities. Workers may be at risk of injury when inspecting, cleaning, or repairing the barriers if the edges are not adequately protected. Sharp edges can also make the maintenance process more time-consuming and complex.

Additional information

| Weight | 6.25 kg |

|---|

Related products

-

Double Height Armco – RSJ Post – 1800mm to suit Crash Barrier (Dig in)

£56.00In stock

Add to basket -

Yellow Armco – 3.20m Effective length Beam – RAL 1023 – Off Road Crash Barrier

£113.00In stock

Add to basket -

Plastic Fish Tail Ends – Black Reflective – to suit Armco Barrier – (AR10B)

£40.00In stock

Add to basket -

Armco 3.20M Effective Length Corrugated Beams – Off Road Crash Barrier – Straight

£55.00In stock

Add to basket